Enhance Your Products with a Custom Membrane Switch for Reliable Performance

Enhance Your Products with a Custom Membrane Switch for Reliable Performance

Blog Article

Discover the Versatile Use Membrane Switch in Modern Electronic Devices

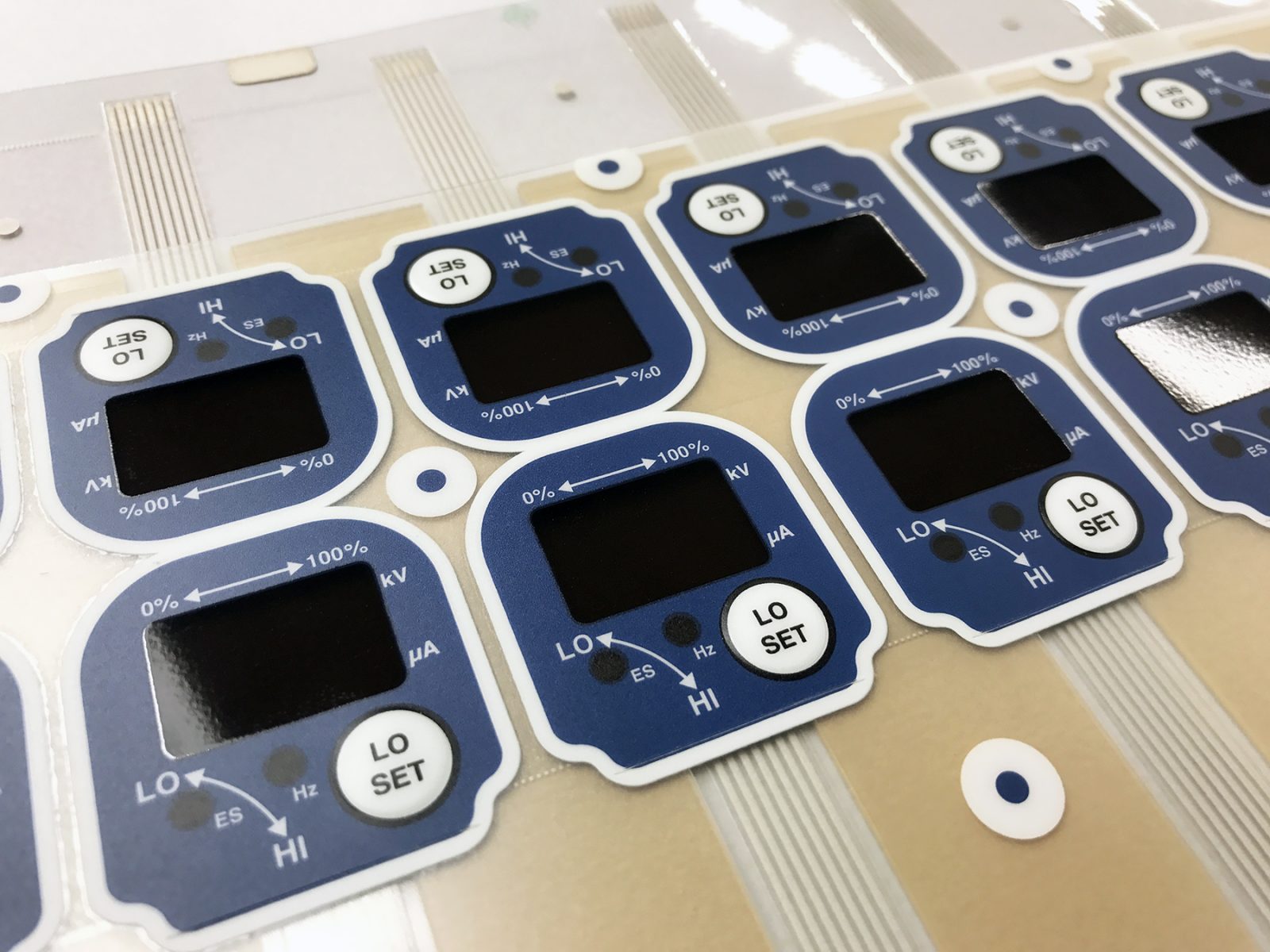

In the world of contemporary electronics, the application of membrane layer buttons is extremely extensive, covering from streamlined customer gadgets to crucial medical tools. These slim, adaptable user interfaces not only streamline tool operation with their responsive responsiveness but additionally dramatically improve resilience by resisting ecological hazards like dampness and dust. As industries remain to develop, the integration of membrane layer switches in equipment style is critical, encouraging not only to fulfill however exceed the rigorous demands of both performance and visual charm. Discover extra regarding just how these elements are shaping the future of technology.

Checking Out the Duty of Membrane Switches Over in Consumer Electronic Devices

Why are membrane layer changes so prevalent in customer electronic devices? The solution exists in their unique mix of dependability, affordability, and versatility. Membrane switches are cost-efficient to manufacture, making them an eye-catching option for high-volume manufacturing common in consumer electronic devices. Their building and construction, featuring a thin, versatile layer that can quickly be integrated right into various devices, enables smooth, small item layouts.

Moreover, these buttons are known for their toughness and low maintenance. From microwave ovens to remote controls, membrane switches provide a practical, user-friendly user interface that supports the vibrant nature of consumer electronics.

Membrane Layer Switches in Medical Instruments: Enhancing Individual Interfaces

Membrane switches likewise play a substantial duty in the realm of medical gadgets, where they boost customer interfaces with their unique advantages. The smooth, covered surface area of membrane layer switches over allows for easy disinfection, lessening the risk of contamination and spread of pathogens.

Membrane buttons additionally add to the durability of clinical tools. Their resistance to fluids and impurities guarantees that crucial equipment continues to be functional in numerous clinical have a peek at this site setups, consisting of surgical treatments where exposure to liquids is usual. This toughness, combined with tactile feedback and inconspicuous style, makes membrane switches over an integral part in enhancing the efficiency and safety and security of clinical device user interfaces.

The Effect of Membrane Activates Industrial Devices Layout

In the world of industrial tools design, the consolidation of membrane layer switches has actually noted a considerable advancement. These buttons have changed my latest blog post just how manufacturers come close to interface functionalities, offering a blend of sturdiness and flexibility that is crucial in severe atmospheres. The slim account of membrane changes permits for even more compact device layouts, while their resistance to chemical, water, and dirt contaminants makes them suitable for commercial setups. This adaptability has assisted in the growth of equipment that is not only extra robust but likewise much easier to keep and tidy, consequently reducing downtime and operational costs.

Moreover, the customizability of membrane changes enables designers to integrate details responsive responses and graphical overlays that enhance the user experience and rise performance. This assimilation sustains operators in achieving accuracy control over complicated machinery. The overall impact is a significant improvement in the performance, dependability, and user-friendliness of industrial devices, lining up with the enhancing demands for technical improvement and operational efficiency in modern-day markets.

Conclusion

Membrane buttons have actually transformed modern electronics, providing smooth, resilient, and adjustable interfaces across various fields. Membrane Switch. In consumer electronics, they enhance the visual and performance of devices. Clinical industries take advantage of their trusted, easy try here to use controls, essential for delicate environments. Similarly, commercial applications value their resilience and effectiveness. This innovation not just meets the demanding conditions of various fields yet also dramatically enhances customer experience, making membrane switches a foundation of modern electronic style.

In the realm of contemporary electronics, the application of membrane layer buttons is remarkably substantial, extending from streamlined customer gadgets to crucial medical gadgets.Why are membrane layer changes so widespread in customer electronic devices? Membrane layer buttons are cost-effective to manufacture, making them an attractive option for high-volume manufacturing common in consumer electronics. From microwave ovens to remote controls, membrane switches provide a practical, user-friendly interface that supports the dynamic nature of consumer electronics.

Report this page